| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : Jinzhen Boiler

Model Number : DZH3-1.0

Certification : ISO9001

Place of Origin : China

MOQ : 1

Price : Negotiable

Payment Terms : L/C, T/T, Western Union

Supply Ability : 80 set per month

Delivery Time : 5-8 working days

Packaging Details : Steam Boiler in nude package, but covered with water-proof covering, accessories in plywood case

Effective area of grate : 3.36m2

Suitable fuel : wood, biomass, coal

Thermal efficiency : 80%

Type : Natural Circulation

Usage : Industrial

Style : Horizontal

Material : Q245R Steel Plate

Output : steam

Structure : Fire Tube

steam capacity : 3000kg/h,3ton/h

Outdoor Industrial Natural Circulation Wood Fire Steam Boiler Supplier In China

DZH series manual coal fired steam boiler, use movable fire grate, equip with blower, draft fan, economizer, deduster, automatic water treatment, water pump, steam header, control cabinet, valves and meters etc auxiliary machines. Due to the less of auxiliaries of this series boiler, so low fault of machines, reduce maintenance cost, easy operation, save time and materials, is an economical boiler type. Suitable for various types of coal fuels, environmental protection, price position moderate, is the first choice of small and medium enterprises who use steam for processing line.

Steam Boiler specification sheet

| Boiler model | DZH1-1.0-T | DZH2-1.25-T | DZH4-1.25-T | DZH6-1.25-T | |

| Rated capacity | ton/h | 1 | 2 | 4 | 6 |

| Rated pressure | Mpa | 1.0 | 1.25 | 1.25 | 1.25 |

| Rated steam temperature | ℃ | 184 | 194 | 194 | 194 |

| Active grate area | m2 | 2.11 | 3.95 | 5.34 | 9.2 |

| Exhaust gas temperature | ℃ | 127.2 | 126.4 | 137.3 | 146.8 |

| Fuel consumption | kg/h | 176 | 352 | 705 | 1058 |

| Thermal efficiency | % | 83.5 | 83.5 | 83 | 83 |

| Weight | ton | 9 | 15 | 18.5 | 25 |

| Dimension | mm | 4320*1825*2685 | 4950*2650*3177 | 5650*2550*3434 | 6930*3020*3664 |

| Delivery mode | / | Package | Package | Package | Package |

Performance advantage

1. The steam boiler is the horizontal quick-loading boiler with natural circulation of working medium.

The boiler heat exchange system is composed of a boiler barrel, a set box and a water cooling wall. The main heating surface is composed of a furnace water cooling wall, part of the boiler barrel and a convection tube bundle inside the boiler barrel.

2. Advanced design performance:

The main heating surface tube of the boiler is made of seamless steel tube of no. 20 low and medium pressure boiler, and the boiler barrel is made of special steel plate for the boiler.The left and right containers are made of seamless steel tubes.

3. The boiler arch is made of fire-resistant concrete.The rear arch is low and long, so it burns well. The wings of the flue and the side wall tiles are made of refractory sintered bricks.Boiler front wall and back wall adopt universal firebrick.

4. Reasonable exhaust ventilation, large combustion chamber and strong applicability of coal.Suitable for all kinds of bituminous coal or anthracite, mixed coal.Well burned.Because the high-temperature flue gas first enters the settlement chamber, and then from both sides enters the two wings of the flue and the front smoke box, so the effect of smoke removal and dust removal is good.

5. Simple water circulation, reasonable structure of pressurized parts, and safe operation under the condition of ensuring water quality.

6. The combustion equipment is a fast-loading grate, which can be manufactured and installed in the factory and directly installed on the foundation after being transported to the site.With reasonable structure, compact, low steel consumption, so that the boiler performance, weight, structure and size compared with domestic products with the same capacity has obvious advanced.

7. Energy saving and environmental protection

biomass steam boiler adopt the latest gasification combustion technology, set up the advanced gasification rotary combustor, built-in cyclone secondary air distribution, make fuel combustion more full.

8, and the use of efficient heat transfer elements - threaded smoke pipe, with a reasonable flow of flue gas, so that the boiler thermal efficiency is higher.The thermal efficiency is over 85%.

9. The steam boiler adopts the green renewable biomass lignin pellet fuel promoted by the state, with zero CO2 emission, smoke emission concentration less than 50mg/m3, smoke blackness less than Ringerman I class, and all indicators meet the national environmental protection standards of the first class.

10. Low operating cost: The fuel lignin biomass pellet used by the boiler is a new type of environmental protection fuel supported and promoted by the state. It is a renewable resource.It has the characteristics of high calorific value, low cost and wide source.Its operating costs are only a quarter of those of electric boilers and less than half of those of oil-fired (gas-fired) steam boilers.

11, high degree of automation: digital integrated controller, according to the user can set the automatic controller burning conditions, simple and convenient operation, automatic ignition, automatic feeding, automatic ash cleaning, gas boiler operation is equally convenient.

Automatic control and fault protection features

Boiler steam pressure automatic regulation system: boiler steam pressure automatic regulation system control system into the state of work, to meet the necessary conditions of combustion: boiler steam pressure is higher than or equal to the set pressure limit, the control system output stop signal.Until the induced draft fan is stopped.

Water supply automatic control: when the system is working or normal, start the water pump, the water pump will work, the water level differential pressure transmitter will detect the water level signal and keep the water level of the drum stable.Ensure the quality of steam.The water level gauge shows the boiler water level.

Manual control: you can also manually control the water pump by touching the button manually on the control panel.

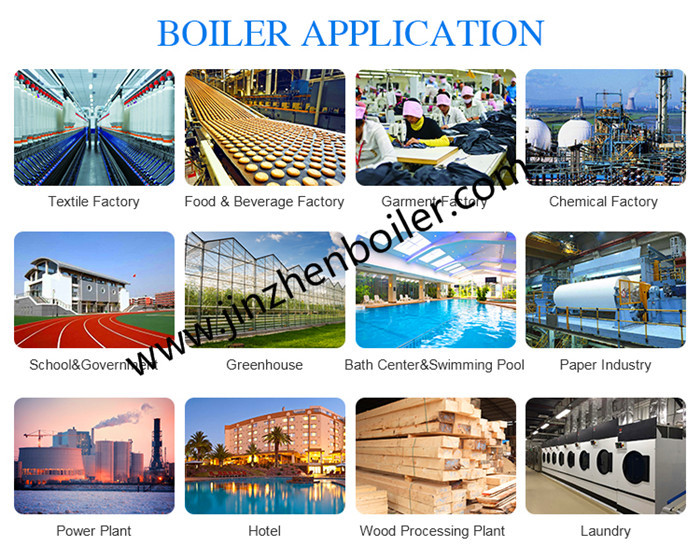

Application for biomass steam boiler

Wood fired steam boiler is suitable for painting room, drying box, drying tower painting line and other purposes.It is especially suitable for central heating in urban residential areas, industrial production, enterprises and institutions, schools, hotels, bath centers and other places where heating, hot water and steam are needed.

|

|

Outdoor Industrial Natural Circulation Wood Fire Steam Boiler Supplier In China Images |